Detail Specifications

[Launched new light-curable resin]

General/12K/8k/mobile/Dental engineering /Elastic/Engineering/Water wash/Alcohol wash/High rigidity/Transparent/ Crystal clear/Stone/Wear-resistant/Polished/High toughness/soft/PP-like/ABS-like/Silicone-like/Nylon-like/PU-like/Like PEEK/Casting/< span style="color:#ff0000">Ceramic-like

Applicable to most LCD light curing machines

(Phrozen series, Anycubic, Elegoo...etc.)

General-white/black/grey:

The resin uses nanopigments, which has high toughness, high success rate, high reactivity, extreme details, and low precipitation. It is a very suitable material for novices to practice or veterans to create.

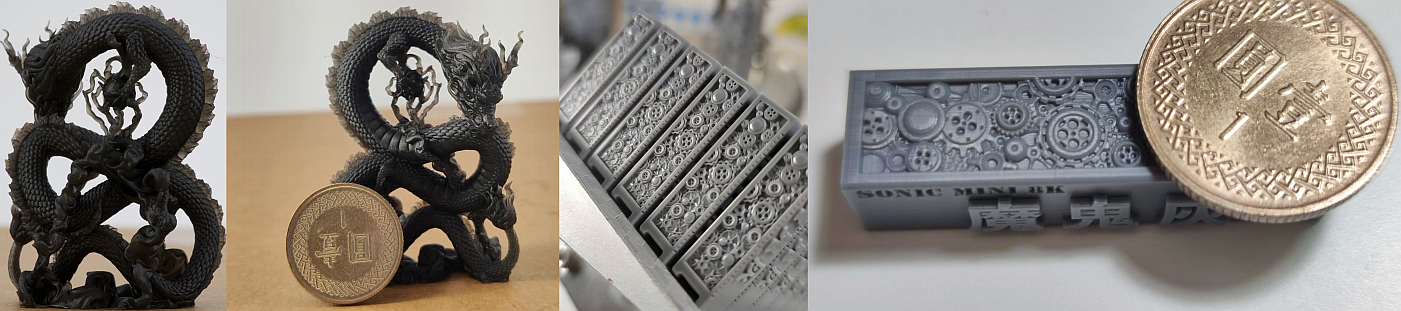

12k-grey:

The resolution is higher, the edge details are sharper, surpassing 19um resolution resin, the quality is stable, and the odor is low. When printing on 4k and 8k machines, you can feel a significant improvement. Increased resilience. Reduce printing deformation, shrinkage, and bubbles. The "full matte" surface improves the texture of the model, improves the printing success rate, and supports less than 8k.

8k-grey/black:

The performance is more detailed than the original general series. The formula is redesigned for Mini 8k (22um) resolution, and the hardness is increased, the reactivity is higher, and the hardness is increased during printing, the shrinkage is low, and the geometric dimensions are stable.

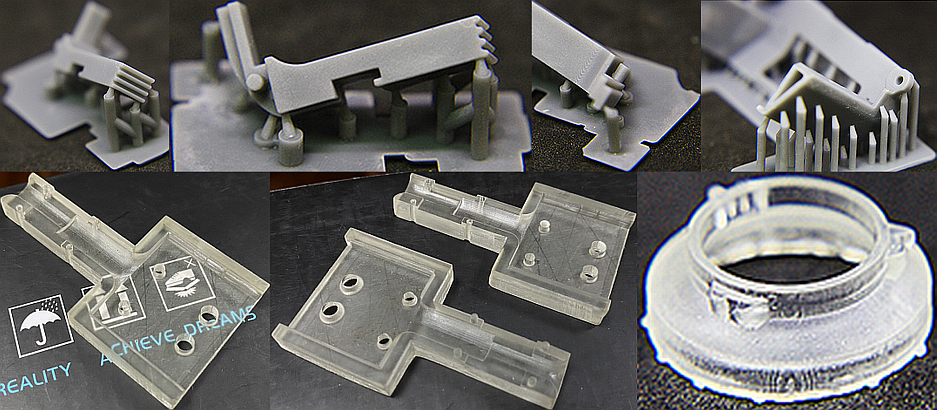

Flow-white/grey/transparent yellow/red

Specially designed for fine printing on lower-end models (e.g. 4k), it can be easily formed under simple conditions;

Slightly tough, not easy to be brittle, medium strength, not easy to shrink and crack, suitable for engineering, structure, and mechanical component proofing.

Flow-white/grey/transparent yellow/red

Specially designed for fine printing on lower-end models (e.g. 4k), it can be easily formed under simple conditions;

Slightly tough, not easy to be brittle, medium strength, not easy to shrink and crack, suitable for engineering, structure, and mechanical component proofing.

[Flow/Transparent Yellow]: You can purchase additional dyes to adjust the color (additional coloring will affect the curing reactivity of the raw materials, please evaluate the addition ratio by yourself), varnish .

Dental engineering/grey/black/transparent (slightly yellow)

Slightly tough, not easy to be brittle, medium strength, not easy to shrink and crack, suitable for dental materials, engineering, structures, and mechanical component proofing.

Transparent: You can purchase additional dye to adjust the color. (Adjusting the color by yourself will affect the curing reactivity of the raw materials, please evaluate the adding ratio by yourself).

[Dental Engineering/Transparent (slightly yellow)]: You can purchase additional dye to adjust the color (adjust the color yourself, which will affect the curing reactivity of the raw materials, please add the proportion yourself Evaluation), varnish.

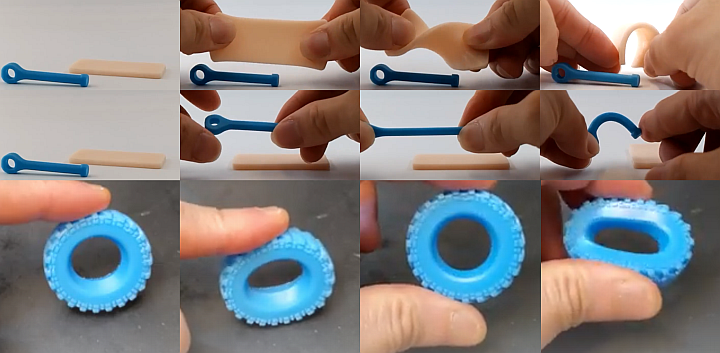

Elastic soft 80/blue and black; elastic soft 60/black

It has a touch similar to soft materials and is suitable for making grips, gaskets, eyeglass hooks, tires, seals, rubber tubes, springs, rubber, shoe insoles, elastic models, bionic structures, etc.< / p>

Engineering-White/Grey:

High hardness, tappable, low shrinkage engineering properties, very high printing rate, suitable for large objects (MEGA 8K recommended).

With a white background, it is difficult to see polishing marks. It will turn slightly yellow after solidification twice. After baking at 40-60 degrees, the yellowing will disappear in 30 minutes and the white surface will be restored.

Engineering washed/white/grey/blue

The tensile strength, surface hardness, and toughness are all good; it can be tapped and drilled, and the details are good and shiny; wash with water (can be used with dishwashing detergent) until there is no emulsion, then dry and perform secondary curing. (Cleaning water, Light, filter and pour) low odor, moderate viscosity.

Alcohol wash-ash

It uses 75%~35% alcohol for cleaning. Compared with ordinary resin, its advantages are:

1. Save on using organic cleaning agents

2. Use 75% disinfectant alcohol which has a less strong smell.

3. Lotion is very convenient to obtain

4. Compared with ordinary resin, easy-to-wash resin supports are easier to remove, have less residue, and have a smoother surface. This advantage not only makes post-processing easier, but also makes the model more beautiful.

5. Very low viscosity, good fluidity, low odor, easy to clean and reduce the chance of printing failure.

6. Even if you use a black and white screen 3D printer, there will be no residue during printing for a long time, and you can print directly using general resin parameters.

High strength-grey/skin:

It has the consistent strength of the Engineering Series, coupled with the characteristics of wear resistance and non-powdering, it is suitable for direct production of finished product surfaces, movable doll rotating shafts, gun mold sliding sleeves, etc.

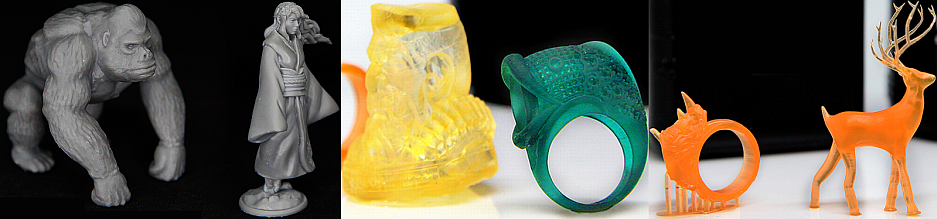

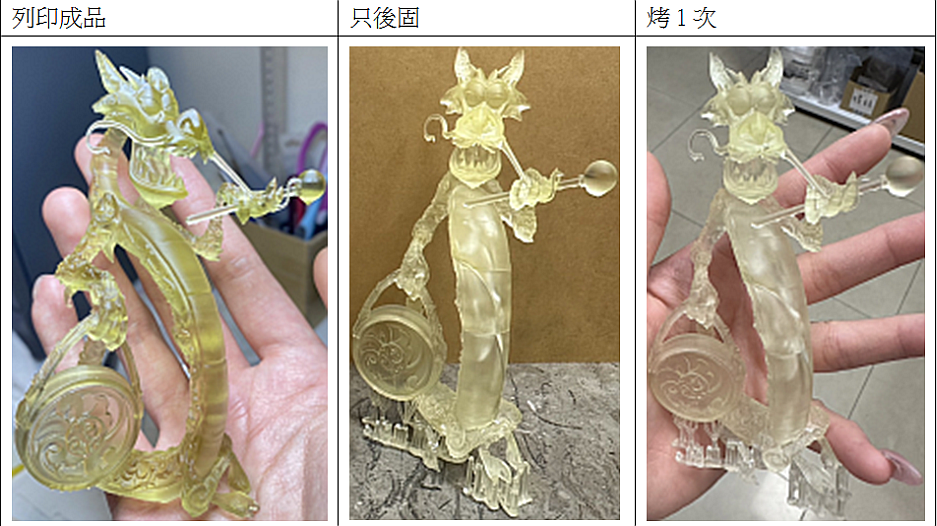

Transparent:

Transparent engineering resin is one of the transparent materials that is easy to print, can be machined, has low shrinkage and high hardness, and can even be coated with transparent paint to achieve an effect similar to glass. The color will turn yellowish green just after solidification. If left for a period of time or baked below 60 degrees for 30 minutes, the yellowing will fade and the original translucency will return.

You can purchase additional dye to adjust the color (adjustment by yourself will affect the curing reactivity of the raw materials, please evaluate the addition ratio by yourself) and varnish.

Jingtou

Smooth and clear as crystal, slightly tough, not easy to be brittle. Medium strength, low shrinkage. Not easy to shrink and crack.

However, the hardness and toughness accuracy of the printed product is slightly inferior to the "toughness transparent (slightly yellow)" resin.

You can purchase additional dyes to adjust the color. (Adjusting the color by yourself will affect the curing reactivity of the raw materials, please evaluate the addition ratio by yourself), gloss Paint.

Stone-white/glitter gray/glitter black and blue:

The surface has a unique texture and luster of stone particles. Small texture defects and printing layer patterns are difficult to detect when printing under specific parameters. After the surface is cleaned, it solidifies like a finished product. It is the best choice for post-painting processing. companion.

Wear-resistant-white

Finished products made of the same materials have excellent wear resistance when they rub against each other or are acted upon by external forces. They will not cause chips (chips) or deformation due to long-term friction. They are especially suitable for gears and long-term moving parts. , model movable joints... and other application fields.

Temperature Resistant - Transparent Brown

High temperature resistant rigid resin, the printed product needs to be baked at 60°C for 2 hours, and then baked at 120°C for another 2 hours before it reaches the desired temperature

Among the current resins, it has the highest strength, highest hardness, and temperature resistance up to 270°C.

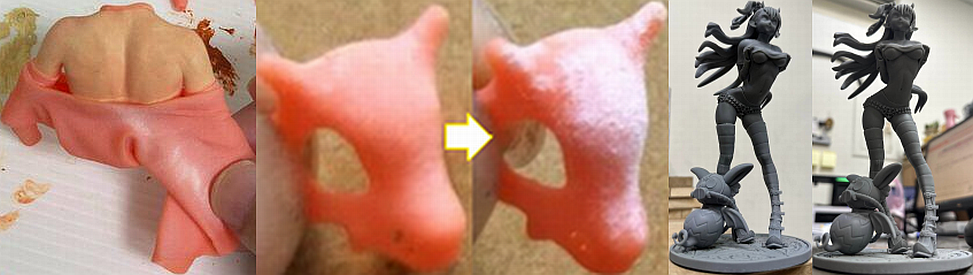

Polished-Red/Grey:

It is an orange-red resin. It is different from other resins in that Feihong resin objects are easy to polish and trim. The polishing marks are not obvious. The surface texture is fine and the color itself is the base color of the skin. After you apply the skin color on the model, it will The skin is rosy, adding a touch of life to the model.

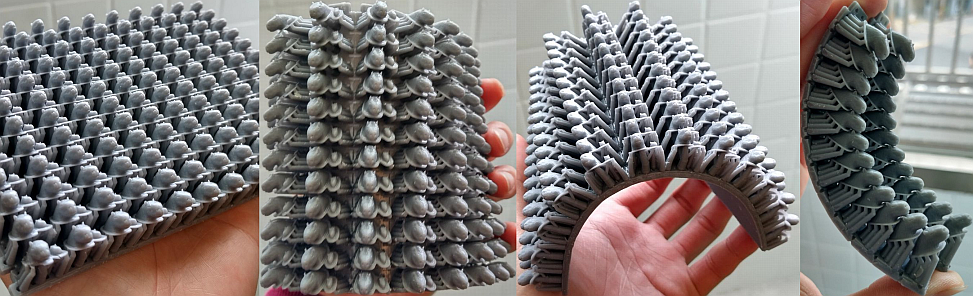

High toughness-white/grey/black/yellow/blue:

Engineering toughened material, unique warm leather feel, excellent toughness and clear details, suitable for various applications such as simulated car tire models, imitation leather feel, anti-slip hard rubber... etc. It will be hard just after solidification, and will return to 71D hardness after being left for a period of time.

Soft-white/black/skin:

Q is soft and rebounds quickly, with excellent toughness. It can rebound slowly after being stretched to a small extent. It can recover quickly after normal pulling and twisting. It is a special material with a tough middle band. If there is a break, it will break from there. The hardness is between Between TPU and silicone. Black - Tensile strength: 1.93MPa, elongation: 125%, hardness: 70A. Skin color - Viscosity: 650cps/25°C, Elongation: 72.3%, Hardness: 55A.

PP-like-white/black

Similar to plastic polypropylene (PP, Polypropylene) physical properties, the finished product has excellent toughness and elasticity,

Very suitable for making industrial models, snap prototypes, bottle caps, battery boxes, parts... etc.

ABS-like-blue gray/dark gray/transparent/luminous

This material has similar properties to ABS and is also grindable and paintable, so it is very suitable for product design, prototype doll production, appearance verification, and display furnishings.

[ABS-like/transparent]: Additional dyes can be purchased for coloring (additional coloring will affect the curing reactivity of the raw materials, please evaluate the addition ratio by yourself), varnish .

Silicone-like-light gray (harder)/grey (softer)

It is a soft material with good rebound and shock-absorbing effect. It can be bent at multiple angles, is not easy to break, and has good molding details. However, like silicone, it has poor rebound.

Nylon-like-white

It has similar properties to nylon, showing superior seismic resistance, toughness and ductility.

Nylon-like-black

It is strong, wear-resistant, smooth, and light in weight; the disadvantage is that it is less heat-resistant, and attention should be paid to the fact that shearing forces can easily cause breaks.

PU-like-iron gray

Similar to PU LIKE, 15 times impact-resistant resin, soft material with a hardness of 80A, harder & tougher than "high toughness".

PEEK-like-black

High-strength resin Tensile Strength can reach 70.5 Mpa; high hardness 90D; high resolution; temperature resistance 89°C and hardness 82~84D before heating; temperature resistance 270°C and hardness 89~90D after baking at 160°C for two hours.

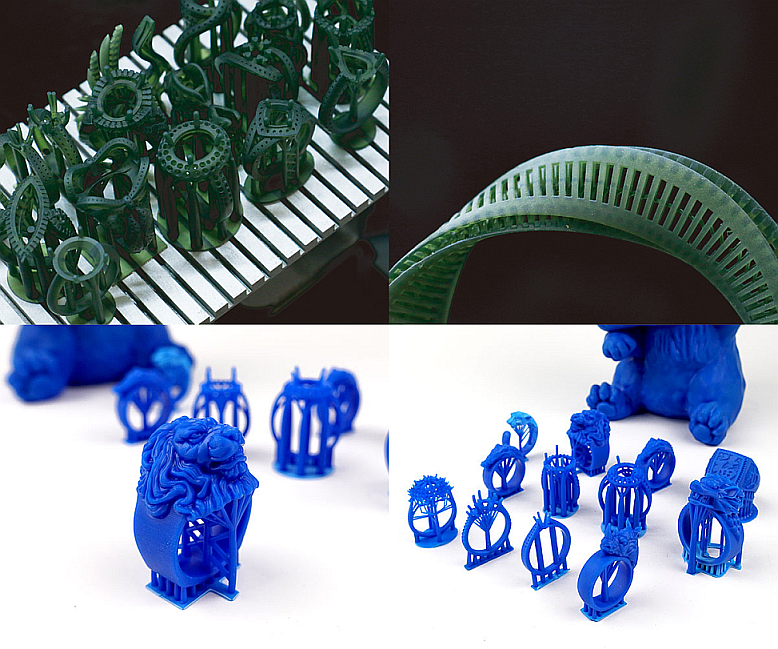

Casting-Red

Special resin for lost-wax casting, with beautiful details, gloss, wax-like effect, low expansion coefficient (low shrinkage), very little residue, and will not cause mold cavity defects or bursting.

Casting - Dark Green/Blue (High Wax Content)

Similar to a wax-like material, it has good combustion characteristics and low shrinkage, so it is suitable for dewax casting (lost wax method).

Ceramic-like blue-gray

This material is similar to ceramic. It can be 3D printed and has excellent hardness, excellent sharpness, heat resistance (high temperature resistance), and chemical stability; it is very suitable for manufacturing 3D printing molds for plastic injection.< br />Continuous heat resistance temperature 100~150°C, the highest temperature resistance can withstand temperatures up to 250°C.

---------------

Other categories:

Cleaning agent

Light-cured finished products, cleaning agents.

Gloss paint

Suitable for transparent resin printed products, 100% acrylic, UV resistant, can be used with a spray gun or varnish brush. It is recommended to apply two layers of varnish with an interval of at least 4 hours.

5-color dye-10ml/PCS/can each

(White. Black. Yellow. Red. Blue)

Special dye for resin, users can adjust the color by themselves.

(Adjusting colors by yourself will affect the curing reactivity of raw materials, please evaluate the adding ratio by yourself).